American Plastics LLC HDPE Pipe Supplier: Tips for Ensuring Compliance and Longevity

Wiki Article

Explore Cutting-edge Solutions Supplied by Leading Pipeline Products Distributors

The landscape of pipeline supplies is swiftly advancing, driven by developments that focus on durability and performance. Leading representatives are introducing ingenious products and methods that redefine typical techniques. From improved stock systems to sustainable techniques, these options are shaping the future of piping systems. As the industry adapts, understanding these advancements becomes vital for stakeholders. What particular improvements are making the most substantial effect?Advanced Pipe Products for Improved Toughness

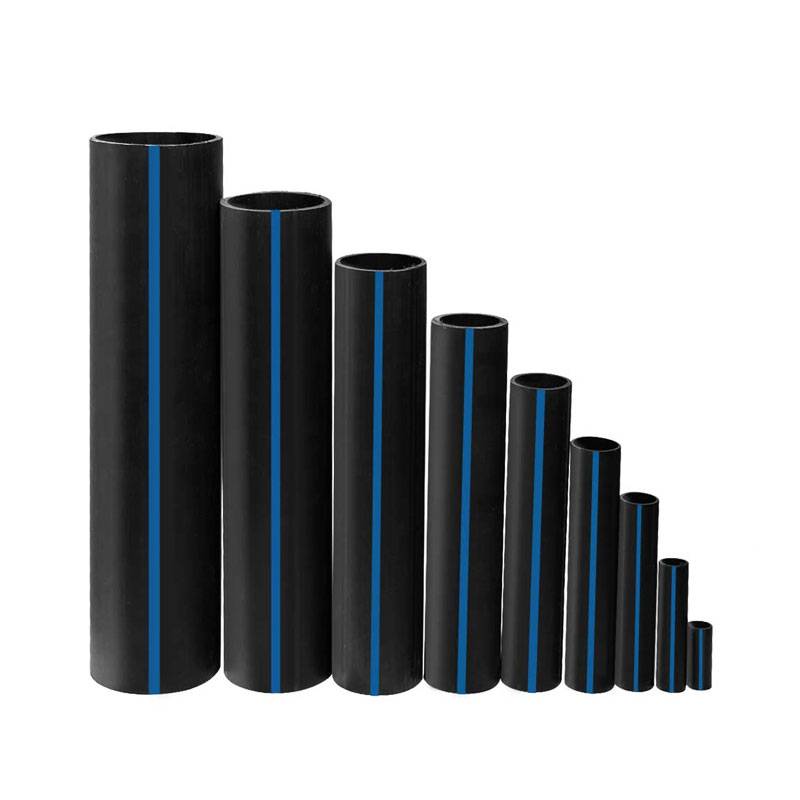

Ingenious production strategies have led to the advancement of lighter and stronger products, which assist in much easier installment and transport. Industries such as oil and gas, water therapy, and construction are significantly embracing these products to ensure reputable solution in tough settings.

The change towards advanced pipe materials not only improves functional efficiency but likewise sustains sustainability efforts by decreasing source waste and enhancing overall system performance. As markets proceed to advance, the need for these long lasting remedies is anticipated to grow.

Smart Stock Monitoring Solution

While markets adapt to evolving needs, smart stock management systems have emerged as necessary devices for optimizing supply chain effectiveness. These systems make use of advanced modern technologies such as synthetic knowledge and maker learning to improve stock processes. By supplying real-time information on supply degrees, demand projecting, and order monitoring, they make it possible for suppliers to make informed choices promptly.

Leading pipe supplies distributors are adopting these innovative remedies to lessen excess inventory and decrease carrying expenses (American Plastics LLC HDPE Pipe Supplier). Automated signals for reordering aid prevent stockouts, making certain that clients obtain prompt distributions. Furthermore, assimilation with various other systems, such as purchase and logistics, improves general operational efficiency

The adoption of clever stock management systems not only enhances precision in monitoring materials yet also promotes partnership between retailers and vendors. As the market accepts electronic change, these systems play a critical function in maintaining competitive advantage and conference customer assumptions in a vibrant marketplace.

Lasting Solutions for Eco-Friendly Projects

Pipe provides distributors are progressively focusing on lasting options to sustain environment-friendly projects. This includes the application of recycled products and the execution of energy-efficient manufacturing procedures. Such efforts not only reduce ecological impact yet also advertise a round economic situation within the industry.Recycled Products Use

As the construction market increasingly accepts sustainability, the use of recycled materials has actually emerged as an essential method for green jobs. Leading pipe materials distributors are responding to this pattern by providing a varied variety of items made from post-consumer and commercial waste. These products not only lower environmental impact but likewise add to circular economic situation concepts by lessening garbage dump reliance. Advancements in handling strategies make it possible for the change of recycled inputs right into premium piping remedies that meet industry criteria. In enhancement, making use of recycled products commonly presents cost benefits, making environment-friendly choices a lot more accessible to specialists. By prioritizing recycled products, distributors play a considerable function in advertising sustainable construction techniques, promoting a greener future for the market.Energy-Efficient Production Processes

The shift towards lasting construction practices extends beyond the usage of recycled products to incorporate energy-efficient manufacturing procedures. Leading pipe materials suppliers are significantly adopting these approaches to minimize their carbon footprints and improve product sustainability. By utilizing sophisticated technologies, such as automated equipment and renewable power sources, manufacturers can significantly decrease energy consumption during manufacturing. In addition, maximizing production methods lessens waste and warranties that sources are made use of efficiently. These energy-efficient processes not only benefit the environment yet also add to cost savings for service providers and project supervisors. As the need for environment-friendly projects expands, taking on these cutting-edge production techniques positions representatives as leaders in sustainability, meeting the assumptions of an eco mindful market.Prefabrication Techniques for Streamlined Construction

Prefabrication techniques are changing the construction sector by using considerable advantages in task distribution. These approaches promote cost-efficiency and time-saving, enabling projects to be finished much faster and within spending plan. Furthermore, improved quality assurance procedures assure that parts satisfy high standards before reaching the job site.Advantages of Prefabrication

While typical construction approaches commonly bring about hold-ups and enhanced expenses, prefabrication supplies a compelling option that boosts and enhances processes efficiency. This method involves making elements off-site in controlled atmospheres, considerably lowering the impact of weather-related disturbances and labor issues. Premade elements can be assembled quickly on-site, reducing construction time and reducing the demand for comprehensive labor sources. Additionally, prefabrication permits for enhanced top quality control, as components are created under standard problems, leading to greater consistency and fewer issues. This technique additionally promotes sustainability by decreasing waste and enhancing product usage. By adopting prefabrication techniques, construction tasks can achieve far better organization, improved security, and an extra predictable timeline, eventually bring about a more effective construction process.Cost-Efficiency and Time-Saving

By leveraging prefabrication strategies, construction projects can accomplish considerable cost-efficiency and time-saving benefits. These techniques enable the assembly of pipe systems and elements in a controlled atmosphere, lessening on-site labor prices and reducing the possibility for construction hold-ups. By producing parts ahead of time, jobs can enhance timelines, as several tasks can happen at the same time rather than sequentially. Furthermore, prefabrication can result in even more accurate budgeting, as products are purchased wholesale and waste is reduced. The decrease in site interruption better contributes to time financial savings, permitting tasks to stick to limited routines. construction groups can allot sources more properly, inevitably resulting in improved profitability and boosted project shipment timelines.Enhanced Quality Assurance

The application of prefabrication methods not only enhances cost-efficiency and time-saving yet additionally significantly improves quality control in construction tasks. By making components in regulated environments, distributors can assure that every item fulfills rigorous high quality criteria prior to go to website reaching the construction website. This procedure reduces on-site variability, minimizing the probability of flaws and revamp. In addition, progressed inspection and testing methods can Our site be quickly incorporated right into the prefabrication process, additional boosting overall quality control. The uniformity accomplished through prefabrication results in a lot more trusted installments, eventually boosting the toughness and performance of the whole system. Subsequently, leading pipe products distributors are progressively adopting these ingenious techniques, placing themselves as frontrunners in delivering high-quality construction options.

Cutting-edge Jointing Technologies

Ingenious jointing modern technologies are changing the method pipeline supplies representatives come close to system setups and repairs. These innovations enhance the signing up with procedure, ensuring stronger, a lot more dependable connections while reducing labor costs and installation time. Methods such as blend welding, mechanical combinings, and solvent sealing offer improved adaptability and durability, fitting numerous materials and ecological conditions.These modern technologies decrease the risk of joint failing, which is vital in keeping system integrity and avoiding pricey downtime. Innovative devices and devices are increasingly being made use of, enabling accuracy in joint alignment and execution. Producers are also developing specialized adhesives and sealants that enhance the efficiency of joints under extreme stress and temperature changes.

As representatives adopt these cutting-edge jointing techniques, they not just improve solution delivery yet likewise add to more sustainable techniques in the sector, addressing both financial and ecological problems effectively.

Innovative Leakage Discovery Solutions

As pipeline materials distributors look for to improve system integrity, cutting-edge leak discovery systems are ending up being vital devices in their operational toolbox - see this American Plastics LLC HDPE Pipe Supplier. These sophisticated systems make use of ingenious technologies such as acoustic sensing units, fiber optics, and thermal imaging to identify leaks with unmatched accuracy. By continually keeping track of pipe problems, they can identify possible failures before they rise into considerable troubles, thus decreasing downtime and repair expenses

Automation Tools for Improved Effectiveness

Leveraging innovative modern technologies continues to reshape the landscape for pipe products distributors, with automation tools playing a substantial role in improving operational effectiveness. These tools improve different processes, including inventory administration, order processing, and customer care. By utilizing software that automates repetitive tasks, distributors can reduce human error and enhance precision in stock levels and order satisfaction.In addition, automation devices make it possible for real-time data analytics, enabling representatives to make enlightened choices based on current market trends and consumer needs. Lots of suppliers are embracing robotic procedure automation (RPA) to take care of regular tasks, freeing employees to concentrate on even more tactical initiatives. This shift not just improves efficiency but additionally adds to quicker turn-around times, eventually enhancing client satisfaction.

In an industry where prompt distribution and integrity are paramount, automation tools represent a vital improvement, ensuring that pipe materials suppliers continue to be responsive and affordable to progressing market demands.

Often Asked Questions

Just How Can I Choose the Right Pipeline for My Job?

To pick the ideal pipe for a project, one have to think about factors such as product type, dimension, stress scores, and ecological conditions, making certain compatibility with job needs and long-lasting resilience for reliable performance.What Aspects Affect the Rates of Pipe Products?

Pricing of pipeline products is influenced by variables such as material type, making procedures, market need, transportation prices, and supplier competition. In addition, local pricing variations and financial problems can greatly affect total costs.Do Distributors Offer Personalized Pipe Solutions?

Yes, many distributors provide customized pipe remedies tailored to details task needs. These offerings typically include different materials, measurements, and designs, permitting customers to meet distinct specs while making sure ideal efficiency and compliance with market requirements.

Exactly how Do I Guarantee Prompt Delivery of My Order?

To guarantee timely delivery of an order, one must validate schedule, develop clear target dates, keep open communication with the distributor, and consider using tracking solutions to check the shipment's development throughout the distribution procedure.What Guarantees Are Offered for Pipeline Products?

Various service warranties for pipeline items generally include restricted lifetime service warranties, product defects protection, and performance assurances. Each representative may provide various terms, so evaluating specific guarantee details with distributors is crucial for notified buying choices.

Pipe supplies representatives are increasingly concentrating on sustainable remedies to support eco-friendly tasks. Leading pipe products suppliers are significantly embracing these approaches to minimize their carbon impacts and improve product sustainability. Ingenious jointing modern technologies are reinventing the way pipeline products distributors come close to system installments and repair services. As pipe materials representatives seek to improve system integrity, sophisticated leak discovery systems are coming to be vital devices in their operational toolbox. Leveraging innovative innovations proceeds to reshape the landscape for pipeline products suppliers, with automation devices playing a significant function in boosting operational effectiveness.

Report this wiki page